The global manufacturing sector is headed for a massive leap into futuristics that feature green, precision and intelligent technologies as showcased at the just-concluded 2024 World Manufacturing Convention in Hefei, China.

The premier event in the manufacturing sector, this convention held Sept.20 attracted top global enterprises, innovative technologies, and cutting-edge concepts to present a feast of technology and innovation to the attendees.

In the Smart Robotics Zone, a variety of robots were showcased with their diverse capabilities.

For example the ‘Qijiang No.2’ humanoid robot, stood at 1.8 meters tall and weighing 60kg, with 38 degrees of freedom throughout its body.

This robot performs basic human limb movements and can also execute delicate tasks like folding clothes, opening bottles, pouring water, and washing dishes with ease.

Moreover, it can navigate rough terrains, resembling an intelligent steel companion, sparking anticipation for the future of automation and intelligence in the manufacturing industry.

Green energy and environmental protection technologies were also significant highlights of this convention.

The Green Manufacturing Zone showcased a wide array of energy-saving and eco-friendly equipment and renewable energy products.

The application of these technologies not only reduces energy consumption and emissions in manufacturing but also provides robust support for sustainable development.

The third-generation locally developed 72-qubit superconducting quantum computer, “Origin Wukong,” from the Hefei High-tech Zone, captured significant interest.

This quantum computer, with over 80% domestic components from hardware to quantum chips, operating systems, and application software, boasts unimaginable computing power, paving new paths for future research, finance, and numerous other fields, shining brightly as a rising star in the quantum technology realm.

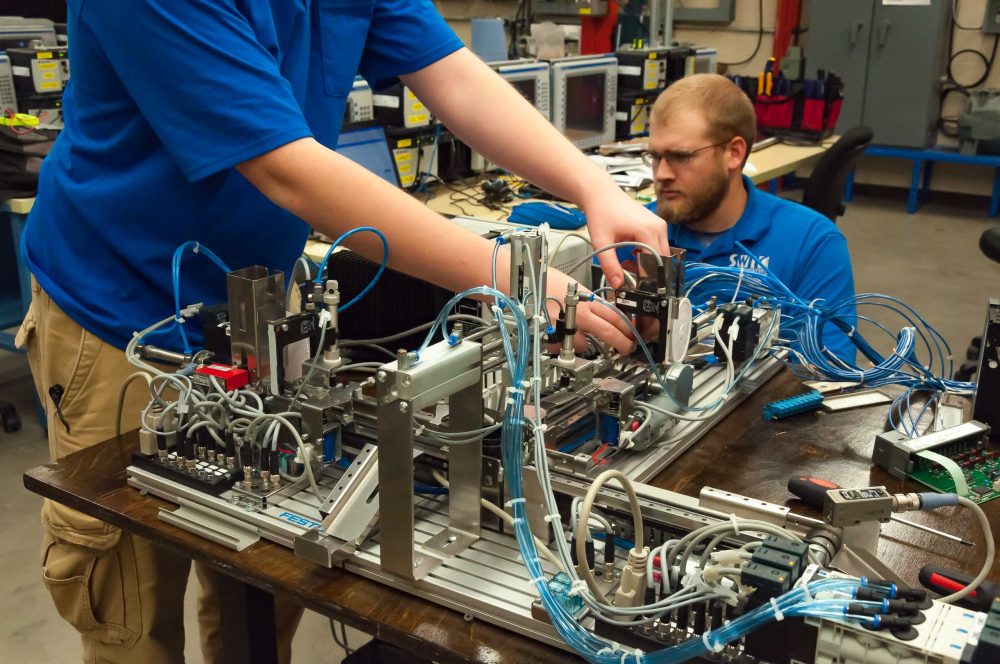

In the 3D Printing Zone, exquisite exhibits left spectators in awe. From intricate mechanical components to lifelike artworks, 3D printing technology, with its precise replication and rapid prototyping capabilities, has brought revolutionary changes to the manufacturing industry.

Inside the zone, staff are busy calibrating equipment, preparing for a spectacular 3D printing showcase.